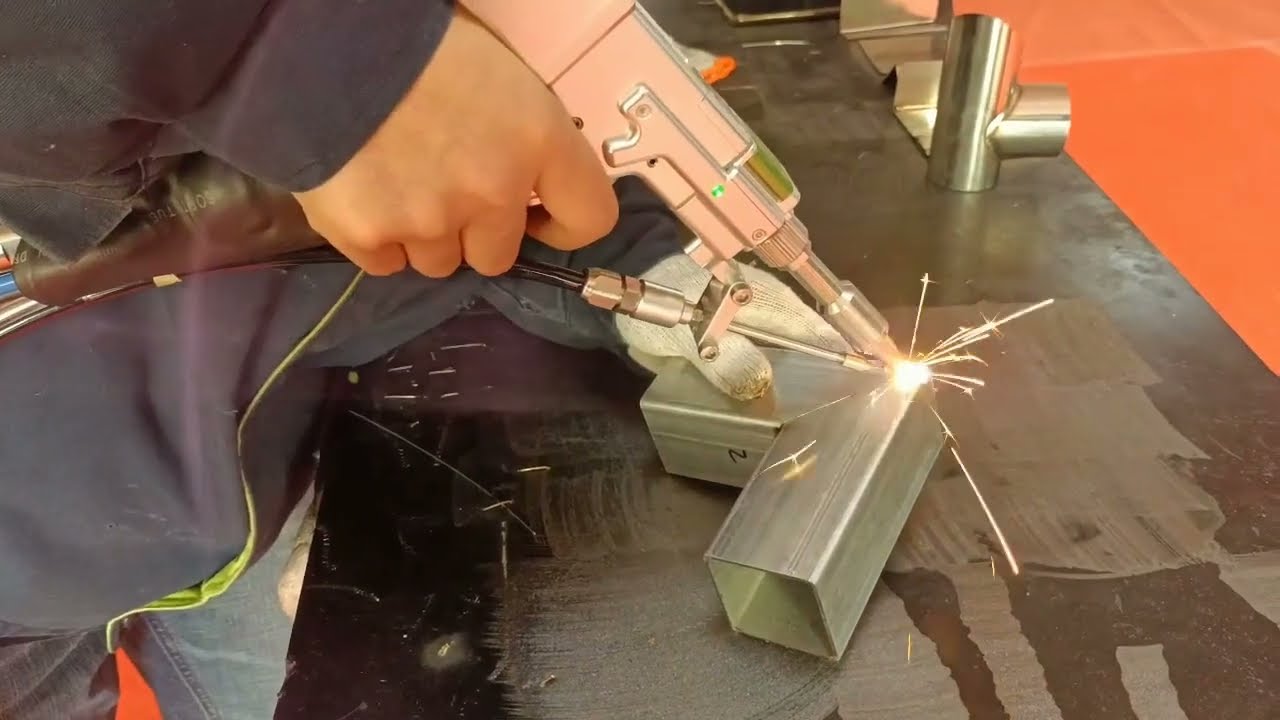

Na ụlọ ọrụ nke ịgbado ọkụ, laser ịgbado ọkụ na-ewere a siri ike na ọkaibe usoro nke isonyere usoro. Ọ na-eji ọkụ ọkụ gbadoro anya nke ukwuu akpọrọ lasers. N'elu ihe a na-ezubere iche, eriri laser na-emepụta okpomọkụ siri ike na ebe kọntaktị na-eme ka ihe ahụ gbazee ma mepụta njikọ siri ike ka ọ na-eme ka ọ dị jụụ ma na-eme ka ọ dị ike.

Mgbado ọkụ laser na-abịa na uru na ọghọm ya. Tụnyere usoro ịgbado ọkụ ndị ọzọ dị ka MIG ma ọ bụ TIG, ịgbado ọkụ laser siri ike karị. Taa, anyị ga-amụta banyere ịgbado ọkụ laser, ike na adịghị ike ya, ojiji, na ihe ndị ọzọ. Anyị ga-atụnyere ịgbado ọkụ laser na ọtụtụ ụzọ ịgbado ọkụ n'isiokwu a.

Yabụ, ka anyị banye n'ime ụwa ịgbado ọkụ laser.

Kedu ihe bụ ịgbado ọkụ laser?

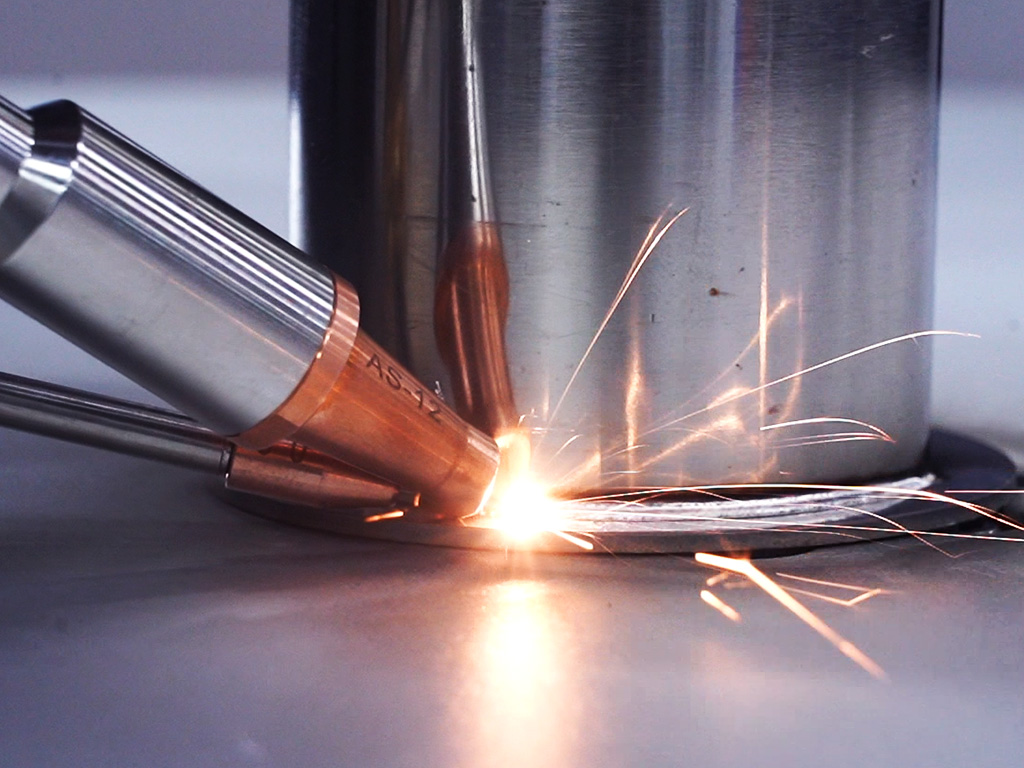

Laser ịgbado ọkụ bụ usoro ịgbado ọkụ nke na-eji lesa laser ibé nke elu okpomọkụ gbazee n'elu metal. Akụkụ gbazere wee jikọta wee sie ike mgbe ọ jụrụ. Dị ka igwe laser ọ bụla ọzọ, igwe ịgbado ọkụ laser na-ejikwa ụfọdụ ihe ụfọdụ akọwapụtara nke lasers gụnyere lasers steeti siri ike, laser gas (CO2 lasers), na diode lasers.

Ịgbado ọkụ dị elu nke nwere ntakịrị mgbagwoju anya na mpaghara ọkụ na-eme ka ọ bụrụ nhọrọ dị mma maka ọtụtụ ọrụ ịgbado ọkụ.

Enwere usoro ịgbado ọkụ ndị ọzọ dị ka ịgbado ọkụ gas metal arc (GMAW/MIG), gas tungsten arc welding (GTAW/TIG), ịgbado ọkụ ọla mkpuchi (Stick), ịgbado ọkụ na-agbado ọkụ, ịgbado ọkụ arc submerged, ịgbado ọkụ ntụpọ na-eguzogide, na ịgbado ọkụ elektrọn.

Laser ịgbado ọkụ akpan akpan bụ kasị bara uru na vasatail n'etiti niile.

Olee otú ọ na-arụ ọrụ?

Ịgbado ọkụ laser na-eji eriri laser lekwasịrị anya elu iji kpoo elu igwe ka ọ gbazee. Mgbe ha jikọtara akụkụ ahụ, a na-ahapụ ha ka ha dị jụụ ruo mgbe ha siri ike.

Enyere ozi onye ọrụ n'okpuru nzọụkwụ site nzọụkwụ.

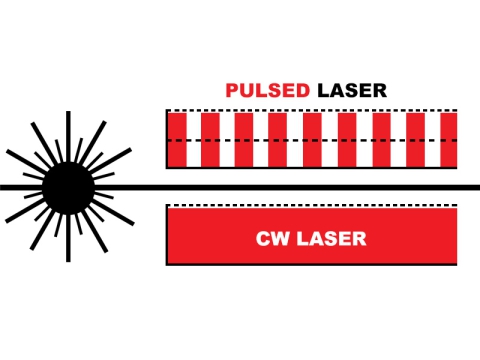

1. Beam ọgbọ: Usoro ịgbado ọkụ na-amalite site na ọgbọ nke ọkụ ọkụ laser dị elu. Ụdị laser dị iche iche, dị ka lasers steeti siri ike, laser gas (dịka ọmụmaatụ, CO2 Enwere ike iji lasers), ma ọ bụ laser diode, dabere na ngwa achọrọ.

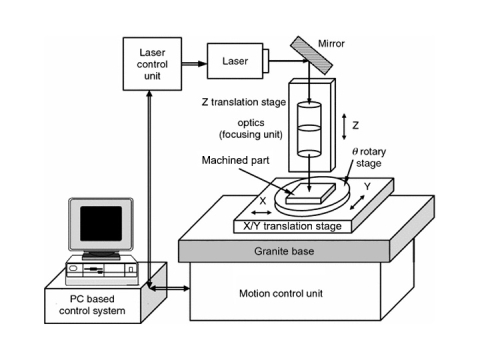

2. Beam na-elekwasị anya: Mgbe ahụ, a na-eduzi eriri laser na ebe a na-elekwasị anya site na iji enyo na anya anya. Igwe ọkụ na-agbaze nke ọma na-agbaze nke ọma na-adabere na izi ezi nke ebe a na-elekwasị anya na okpomọkụ.

3. Nkwadebe ihe: Tupu ịmalite usoro ịgbado ọkụ, nkwadebe ihe dị mkpa. Nke a na-agụnye ihicha, njigide, na ọgwụgwọ elu.

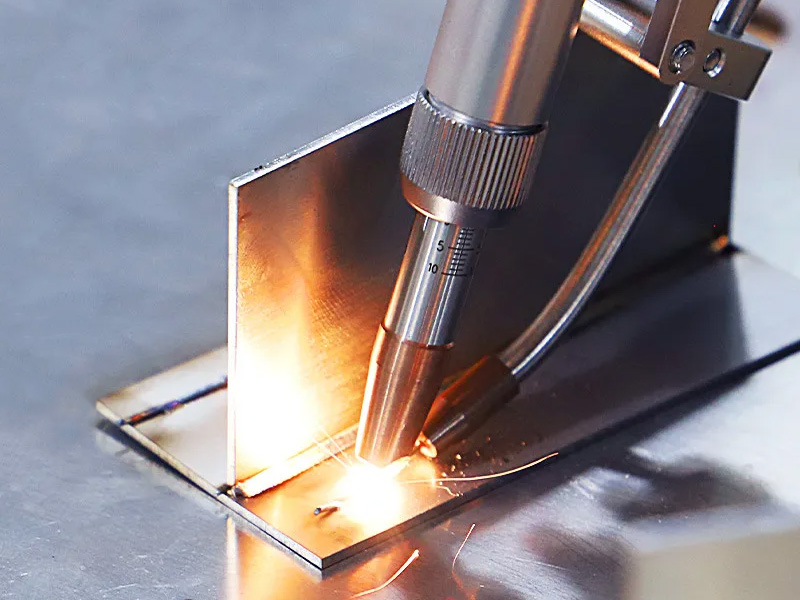

4. Usoro ịgbado ọkụ: Lekwasị anya n'ibe laser n'elu ihe a kwadebere nke ọma. Ebe a na-eduzi nke elu na-agbaze site na ọkụ gbadoro anya nke laser.

5. Nhazi Weld: Ihe ndị a wụrụ awụ na-ejikọta ma na-etolite nkwonkwo siri ike. Iji kwalite ike nkwonkwo na mejupụta oghere enwere ike iji ihe nzacha ọzọ.

6. Ntu oyi na nkwụsi ike: Ozugbo ịgbado ọkụ ahụ zuru, ihe ndị a wụrụ awụ na-adị ngwa ngwa ma na-eme ka ọ dịkwuo mma, na-eme ka njikọ siri ike n'etiti ebe ndị jikọtara ọnụ. Iji wedata mgbagwoju anya njikwa jụrụ oyi dị ezigbo mkpa.

7. Post-weld nnyocha: Nyochaa ịgbado ọkụ maka àgwà na iguzosi ike n'ezi ihe. Usoro mmecha ndị ọzọ dị ka egweri, polishing, ma ọ bụ mkpuchi nwere ike ịchọrọ dabere na ịgbado ọkụ.

Ọgbadọ ọkụ laser siri ike?

Ee, a na-ewere ịgbado ọkụ laser dị ka usoro ịgbado ọkụ siri ike na nke a pụrụ ịdabere na ya. Ihe kpatara ịgbado ọkụ laser bụ usoro ịgbado ọkụ siri ike ka enyere n'okpuru.

• Nkenke na njikwa

Njikwa ziri ezi n'elu welding parameters dị ka ike, ọsọ, na ilekwasị anya na-enye ohere ka a na-edobe ịgbado ọkụ na ihe onwunwe. Nke a na-ebute nkwonkwo weld siri ike.

• Mpaghara Okpomọkụ metụtara Opekempe (HAZ)

Oghere ndị a gbadoro anya na-ebute mpaghara okpomọkụ metụtara kacha nta. Nke a na-ebelata ndakpọ okpomọkụ, nrụgide fọdụrụnụ, na ike ọgwụgwụ nke ihe. N'ihi ya, ihe eji arụ ọrụ nke nkwonkwo welded na-adịkarị elu karịa ndị a na-enweta na ụzọ ịgbado ọkụ ndị ọzọ

• Emetụ omimi

Laser ịgbado ọkụ nwere ike nweta miri penetration na elu akụkụ ruru. Ịgbado ọkụ n'ime ihe ndị siri ike na-aghọwanye ohere maka nke ahụ. Ọ na-akwalite iguzosi ike n'ezi ihe nke nkwonkwo.

• Nnukwu ume ike

Njupụta ike dị elu na-eme ka agbaze na-arụ ọrụ nke ọma na ngwakọta nke ihe. Nke a na-ebute njikọ metallurgical siri ike. Nke a dị elu ike njupụta na-emekwa ka ịgbado ọkụ nke ígwè na ndị na-abụghị ferrous alloys.

• Usoro enweghị kọntaktị

Ịgbado ọkụ laser na-ebelata nrụrụ anụ ahụ na mmetọ nke ihe agbadoro anya ebe ọ bụ usoro ịgbado ọkụ na-abụghị kọntaktị.

Ihe na Aka

Laser ịgbado ọkụ bụ a vasatail na bara uru usoro maka a dịgasị iche iche nke ịgbado ọkụ ọrụ. N'agbanyeghị nke ahụ, mgbe ụfọdụ, ọ naghị enye mmepụta dị mkpa na-atụnyere ụfọdụ ụzọ ịgbado ọkụ ndị ọzọ. Ka anyị leba anya na ike na adịghị ike nke ịgbado ọkụ laser n'akụkụ n'akụkụ.

| Uru | ọghọm |

|---|---|

| Na-enye ohere maka ịgbado ọkụ na-achịkwa nke ukwuu, dị mma maka akụkụ mgbagwoju anya na nke siri ike | The mbụ ego maka laser ịgbado ọkụ akụrụngwa bụ dịtụ elu tụnyere omenala ịgbado ọkụ ụzọ |

| Enwere ike ịgbanye ihe dị iche iche, gụnyere ọla, plastik na ihe ndị yiri ya | Enwere ike ọ gaghị adabara maka ihe ndị dị oke oke ma ọ bụ ndị nwere elu na-egbuke egbuke, nke nwere ike ịtụgharị ma ọ bụ gbasasịa eriri laser |

| Na-ebelata ndakpọ okpomọkụ na mmebi ihe, na-echekwa ihe eji arụ ọrụ nke ihe ndị gbara ya gburugburu | Ọdịdị ahịrị anya nke eriri laser na-amachibido iji ya na nkwonkwo ịgbado ọkụ na-adịghị mfe ịnweta ma ọ bụ nwee ọdịdị geometric siri ike. |

| Nwere ike ịgbado ọkụ dị elu, nke na-abawanye nrụpụta ma na-ebelata oge nrụpụta | |

| Na-enweta welds siri ike n'ime ihe ndị gbara ọkpụrụkpụ nwere oke akụkụ dị elu, ọtụtụ mgbe n'otu ngafe | |

| Ejikọtara ngwa ngwa n'ime sistemu nrụpụta akpaaka, na-emezi arụmọrụ yana nkwụsi ike |

Otu esi emeri njedebe nke ịgbado ọkụ laser!

Mgbado ọkụ laser nwere ike ịbụ nnukwu ohere ma ọ bụrụ na ejiri ya n'ụzọ ziri ezi. Ee, ọ na-abịa na njedebe ụfọdụ mana ị nwere ike imeri ọtụtụ n'ime ha. Yabụ, otu esi eme nke ahụ?

Ọnụ ego akụrụngwa dị elu

• Mee nyocha nke ọma na-erite uru. Tụlee ihe nchekwa ogologo oge site na mmụba arụpụtaghị ihe.

• Chọpụta ego ma ọ bụ ịgbazinye nhọrọ.

• Malite na ntinye ego kacha nta na igwe. Nke nta nke nta na-abawanye ego.

Oke ihe onwunwe

• Jiri mkpuchi ma ọ bụ ọgwụgwọ elu na ihe na-atụgharị uche. Nke a ga-eme ka nnabata laser dịkwuo elu ma belata okwu ntụgharị uche.

• Na-ebuli usoro laser ka ọ dabara n'ihe onwunwe na ọkpụrụkpụ.

• Jikọta ịgbado ọkụ laser na ụzọ ịgbado ọkụ ndị ọzọ (dịka MIG ma ọ bụ TIG).

Ịnweta nkwonkwo nwere oke

• Iji ogwe aka robotik na sistemu akpaaka ga-enye ohere ịnweta nkwonkwo siri ike iru.

• Chepụta ihe ndozi na jigs omenala.

• were multi-axis laser ịgbado ọkụ usoro

Na mgbakwunye, iji nwayọọ nwayọọ na mmejuputa ngwaahịa ndị dị ugbu a, na-eme nyocha ndakọrịta, na ịmalite ọrụ pilot nwere ike ịkwalite arụmọrụ nke igwe ma belata njedebe nke ọma.

Mgbado ọkụ laser VS MIG

| atụmatụ | Eldgba ọkụ Laser | M |

|---|---|---|

| Isi Iyi | Igwe ọkụ laser | Igwe ọkụ eletrik |

| nkenke | Nnukwu elu | agafeghị oke |

| Mpaghara Okpomọkụ metụtara | Obere | Ibu |

| Ọsọ ịgbado ọkụ | High | Ọkara ala ruo ala |

| Ihe odide | Miri, na-abụkarị otu ngafe | Ọ dị mma, nwere ike ịchọ ọtụtụ ngafe |

| Ndakọrịta ihe | Nnukwu oke, gụnyere ihe siri ike ịgbado ọkụ | Ogologo oke, ọla nkịtị |

| ọsụsọ | Opekempe na ọ nweghị | Na-emepụta spatter |

| Ọnụ akụrụngwa | High | Lower |

| Nchoputa nka | Ọzụzụ dị elu, ọpụrụiche chọrọ | Ọ dị oke oke, dị mfe ịmụta |

| Nnweta nkwonkwo | Na-achọ ahịrị-anya | Agbanwe agbanwe |

| Automation | Ngwa ngwa akpaaka | Obere obere akpaaka |

| Safety | Ihe egwu dị egwu sitere na lasers ike dị elu | Na-achọ ịkpachara anya mana ọ ka mma karịa |

Mgbado ọkụ laser VS TIG

| Akụkụ | Eldgba ọkụ Laser | TIG ịgbado ọkụ |

|---|---|---|

| Nkenke na njikwa | Oke oke oke, dị mma maka usoro mgbagwoju anya na akpaaka | Elu nkenke na njikwa akwụkwọ ntuziaka, dị mma maka welds zuru ezu na nke dị elu |

| Mpaghara Okpomọkụ metụtara (HAZ) | Obere HAZ, na-ebelata ndakpọ okpomọkụ na ichekwa ihe onwunwe | Na-ebelata HAZ, mana ọ bụghị dị ka ịgbado ọkụ laser |

| Speed | Ịgbado ọkụ dị elu na-abawanye arụpụtaghị ihe | Ọsọ ịgbado ọkụ nwayọ nwayọ na-ebelata nrụpụta |

| egosipụta ọtụtụ ihe | Kwesịrị ekwesị maka ihe dị iche iche, gụnyere ọla, plastik, na ihe ndị yiri ya | Ọ dị mma maka ọla dị iche iche, ọkachasị ndị na-abụghị ferrous, mana ọ dị obere na plastik |

| Nchoputa nka | Na-achọ ọzụzụ pụrụ iche na nka | Na-achọ nka na ahụmịhe dị ukwuu maka nsonaazụ kacha mma |

| -eri | Ọnụ akụrụngwa mmalite dị elu | Ọnụ akụrụngwa na-agafeghị oke, dị elu karịa ụfọdụ ụzọ ndị ọzọ |

| ngwa | Kwesịrị ekwesị maka ngwa nrụpụta dị elu, akpaaka na nke dị elu | Kachasị mma maka welds dị elu yana njikwa akwụkwọ ntuziaka, dị ka na mbara ikuku, ụgbọ ala, na ọrụ nka nka. |